We source only premium-quality raw materials to ensure exceptional conductivity, low resistance, and long-term performance.

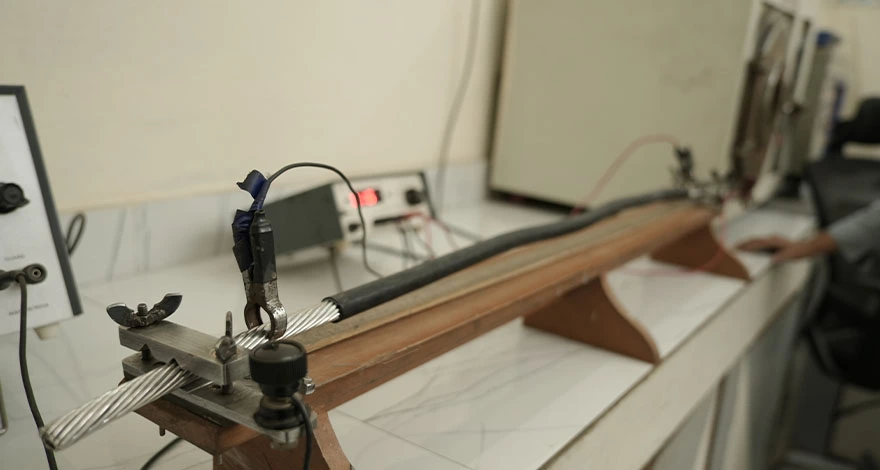

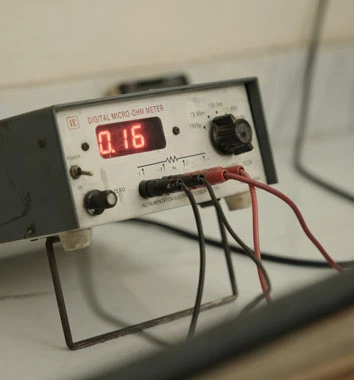

Equipped with modern testing equipment, our labs monitor every production stage — ensuring compliance with national and international quality benchmarks.

Our undying commitment to quality reflects in the decisions we make, the care we take, and the trust we build with every product we deliver. It’s about integrity in every layer, precision in every process, and pride in every result. Because when our cables carry power, they also carry our promise.

From high-voltage and flame resistance to tensile strength and insulation checks — each product is validated through multi-layer testing protocols.

Measures the electrical resistance of the conductor to ensure optimal conductivity and energy efficiency.

Applies high voltage to the insulation to verify its ability to withstand electrical stress without breaking down.

Checks the resistance between conductor and insulation to ensure minimal leakage current and high insulation integrity.

Assesses the mechanical strength of the conductor and sheath, ensuring the cable can withstand pulling forces during installation.

Determines the ductility of insulation and sheath materials, ensuring flexibility and resistance to cracking under stress.

Evaluates the cable’s ability to resist ignition and prevent fire propagation, critical for safety in industrial and residential environments.